Industrial Machine Vision Bar Light Combined Series

Bar light combined are industrial LED lights for illuminating products in machine vision applications like surface defects on metal parts, character inspection on printed material, inspection of PCB components and positioning and recognition of large field objects. Our bar light combined are available in different sizes and light colors. The standard colors are White, Red, Green or Blue. On request also UV and IR bar light combineds are possible. If you can't find the right size, we can customize the bar light combined to fit you illumination request.

When to use bar light combined in your machine vision application?

Barlights are the most commenly used lights in machine vision applications. They are very versatile. You can use them in applications where you are inspecting:

- Objects that are flat. In case an object is reflective you need to adjust the angle of the barlight that there is no direct reflection into the camera image

- Objects that are not flat and not reflective. These diffuse objects can always be illuminated with bar light combineds

In case an object is not flat and reflective, we strongly recommend to use a domelight for illuminating your product.

|

|

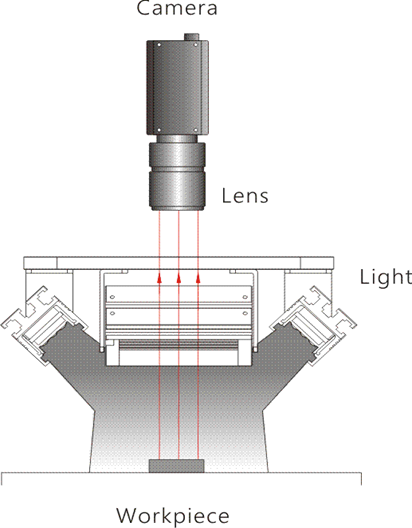

How to use bar light combined for illumination

Bar light combined are commenly used in pairs of at least 2 pieces. For more complex applications, 4 or even more bar light combineds are used. Using our bar light combined mounting brackets you can optimize the angle of the bar light, making sure there is minimal reflection. Optionally we have diffusers and polarizers available. We recommend to use the powersupplies as indicated in the datasheet to control the brightness of the bar light combined. Additionally these powersupplies give you the option to trigger the bar light combined. Triggering the bar light combined will increase the lifespan of the bar light combined.

Overview of bar light combined

|

Model

|

Color

|

Camera Window (mm)

|

Voltage

|

Power

(R)*

|

Power

(W/B/G)*

|

Dimensions B

(mm)

|

Express Stock

|

|

VA1-BLM3-41x41

|

W/R/G/B

|

41x16

|

24V

|

4x1.3W

|

4x1. 7W

|

112x112x37.5

|

No

|

|

VA1-BLM3-80x41

|

W/R/G/B

|

101.5x62.5

|

24V

|

4x2.7W+4x1.3W

|

4x3.4W+4x1.3W

|

280x280x37.5

|

No

|

|

VA1-BLM3-80x80

|

W/R/G/B

|

101.5x101.5

|

24V

|

4x2.7W

|

4x3.4W

|

151x151x37.5

|

No

|

|

VA1-BLM3-119x119

|

W/R/G/B

|

140.5*140.5

|

24V

|

4x4W

|

4x5.1W

|

190x190x37.5

|

No

|

|

VA1-BLM3-218x146

|

W/R/G/B

|

235.5x163.5

|

24V

|

2x7.8W+2x5.2W

|

2x13.7W+2x8.7W

|

307.5x235.5x37.5

|

No

|

|

VA1-BLM3-218x218

|

W/R/G/B

|

235.5x235.5

|

24V

|

4x7.8W

|

4x13.7W

|

307.5x307.5x37.5

|

No

|

|

VA1-BLM3-290x290

|

W/R/G/B

|

307.5x307.5

|

24V

|

4x10.5W

|

4x18.2W

|

379.5x379.5x37.5

|

No

|

|

VA1-BLM3-386x386

|

W/R/G/B

|

403.5x403.5

|

24V

|

4x14.6W

|

4x25.3W

|

475.5x475.5x37.5

|

No

|

*Tolerance +/- 10%

Download bar light combined datasheet

In our bar light combined datasheet you find the mechanical dimensions, wavelengths, operating temperature, compatible powersupplies and so on. Login using your email address and get instantly access to our bar light combined datasheets.

Production and quality control of bar light combineds

Our LED bars are produced with a strict process of quality control, to ensure the reliability and consistency of our bar light combined. Upon receiving a new batch of LEDs, the quality department completes a comprehensive check to test whether the wavelength falls within the specified tolerances. Approved LEDs are stored in a climate chamber, ready for use in production. The next stage is automated and involves placing the LEDs on a PCB that fits the bar light combined, which is then followed by an inspection and soldering. Moving along the production line, the LED boards for bar light combineds are Assembled into the mechanical housing of the bar light combined. Post-assembly, the bar light combineds undergo testing to ensure that the bar light combined performs according to its specification. This critical phase ensures that each unit meets our uncompromising quality standards. The production process of the bar light combined may also include the creation of a diffuser or polarizer. The diffuser is cut automatically and every batch of diffuser plates undergoes transparency testing before they are cut into the correct shape. It is standard that all of our bar light combineds are equipped with a diffuser. The final step involves a comprehensive quality check, where the intensity, voltage, and current of each light are meticulously measured. This step guarantees that all machine vision lights that leave our facility meet the required specifications. To further ensure the long-term consistency of our bar light combineds, we have established a room dedicated to light-source age testing. During the R&D phase of a new bar light combined, the bar light combined will be continuously on for 1 week, while the temperature is monitored. For every new production run of bar light combineds, each bar light combined will be continuously powered for 12 hours, ensuring that the quality and output of our machine vision lights remain uniform over time.